Cable Sizing Calculator

Size copper or aluminum cables by allowable voltage drop or check voltage drop for an existing cable in single- or three-phase systems.

Calculation Steps

Topic · Cable sizing

Cable Sizing Calculator – voltage drop, conductor area & design tips

Learn how cable sizing works, which formulas sit behind the Cable Sizing Calculator, and how to interpret the results for real-world electrical design. This guide walks through voltage drop, conductor cross-section, and practical design limits for both copper and aluminum cables.

How to use the Cable Sizing Calculator step by step

The Cable Sizing Calculator above is built to answer two closely related questions: “What minimum conductor area do I need for a given voltage drop limit?” and “What voltage drop will I get from the cable I already have?”

In size mode, the calculator works backwards from your allowable voltage drop to find the minimum cross-sectional area. In check mode, it uses your existing cable size to compute the resulting voltage drop and percentage. You can always switch modes using the Calculation Mode selector near the top of the form.

If you prefer to see the results first and read theory later, you can also scroll down to the worked examples section, review the scenarios, and then manually copy the same values into the calculator to replicate the results.

-

1

Select the calculation mode. Choose “Size cable by voltage drop” to find the minimum cable area, or “Check voltage drop for an existing cable” if you already know the cable size and want to verify that the drop stays within your limit.

-

2

Set system type and material. Pick single-phase or three-phase under System Type, then select copper or aluminum under Conductor Material. The calculator internally adjusts for the geometry factor \(k_{\phi}\) (2 for single-phase, \(\sqrt{3}\) for three-phase) and resistivity of the selected metal.

-

3

Enter supply voltage, load current and cable length. Use line-to-line supply voltage, design load current, and the one-way cable length from source to load. Units can be switched (for example V/kV, m/ft) using the drop-downs next to each input; the calculator converts everything back to consistent base units behind the scenes.

-

4

Provide the missing design parameter and calculate. In size mode, enter an allowable voltage drop percentage (e.g. 3 %). In check mode, enter the existing cable cross-section (mm² or kcmil) and, optionally, a comparison voltage-drop limit. Then click the Calculate button. The result panel shows either the minimum required conductor area or the resulting voltage drop and percent of supply.

What is cable sizing in electrical design?

Cable sizing is the process of choosing a conductor cross-section that can safely and efficiently carry electrical current from source to load. In practice you are balancing several concerns:

- Voltage drop along the cable should stay within recommended limits so that equipment sees the voltage it was designed for.

- Current-carrying capacity (ampacity) must be adequate so the cable does not overheat in the installation conditions.

- Mechanical and installation constraints such as bending radius, terminations and conduit fill must still be satisfied.

The Cable Sizing Calculator focuses on the voltage drop side of the design. It assumes you already have (or will later confirm) an appropriate ampacity from code tables or manufacturer data. This is why the inputs emphasize system type, voltage, current, material and length: these are the variables that dominate how much the voltage falls between source and load.

Whenever current flows through a cable with electrical resistance, some energy is lost as heat. That loss appears as a voltage reduction: the load sees a lower voltage than the source. Too much drop can cause dim lights, motor torque problems, overheating, or nuisance trips, even if the cable is technically large enough from an ampacity standpoint.

A sizing workflow typically follows this loop:

- Estimate load current from power and power factor, or take it from nameplate or upstream design.

- Choose a tentative cable size and type based on ampacity tables and installation details.

- Compute the voltage drop for that cable size and circuit length.

- Increase or decrease the cable size until both ampacity and voltage drop are acceptable.

The calculator streamlines this by performing the voltage-drop math instantly. You can use it either early in the design to find a reasonable starting size, or as a final check before issuing drawings or selecting an exact catalog part.

Core formulas for voltage drop & cable cross-section

At the heart of the Cable Sizing Calculator is the relationship between voltage drop, current, cable resistance and conductor area. For a cable with resistance \(R\) per conductor, carrying current \(I\), the basic voltage drop magnitude is

where \(k_{\phi}\) is the geometry factor: \(k_{\phi} = 2\) for a single-phase 2-wire circuit and \(k_{\phi} = \sqrt{3}\) for a three-phase system.

Cable resistance depends on conductor resistivity \(\rho\), length \(L\) and cross-sectional area \(A\):

Substituting this into the voltage drop formula gives a direct relationship between voltage drop and area:

If you know the maximum allowable voltage drop \(\Delta V_{\text{max}}\), you can rearrange the equation to solve for minimum required cross-sectional area:

The calculator hides these details but follows the same logic. When you choose “Size cable by voltage drop (find minimum area)”, it converts your inputs to base units, selects resistivity for copper or aluminum, applies the appropriate \(k_{\phi}\) based on system type, and computes \(A_{\text{min}}\) in mm² before optionally converting to kcmil.

In practice, designers usually specify voltage drop as a percentage of supply voltage:

The calculator allows you to enter the allowable drop directly in percent. Internally it computes \(\Delta V_{\text{max}} = V_{\text{supply}} \times \%V_{\text{drop}}/100\) and substitutes that into the area formula. In check mode, it does the reverse: it finds \(\Delta V\) from your existing cable area and then reports both volts and percent of supply.

- Increasing cable length \(L\) or current \(I\) increases voltage drop and calls for a larger conductor.

- Switching from copper to aluminum increases resistivity \(\rho\), which also increases the required area.

- Raising the allowable voltage drop (for a non-sensitive load) allows a smaller cable, but only within code and equipment limits.

Design limits: voltage drop, ampacity & safety

Even though the Cable Sizing Calculator is voltage-drop focused, real designs must satisfy both voltage drop and ampacity criteria. A cable that meets a tight drop limit over a long distance will almost always satisfy ampacity, but the reverse is not guaranteed: a cable sized only for ampacity might produce too large a voltage drop at the far end.

Common design practice is to set conservative voltage drop limits such as:

- Feeder circuits: on the order of a few percent of supply voltage.

- Branch circuits and total feeder + branch: slightly higher but still modest percent limits.

Exact numbers depend on local standards, the type of installation, and how sensitive the loads are. Motors, for example, may need a tighter limit during starting to avoid excessive current and torque issues. Electronic loads may also specify a narrow acceptable input voltage range.

After you obtain a minimum area from the calculator, you should still:

- Cross-check ampacity using cable ampacity tables or manufacturer data for your installation method (in conduit, buried, free air, tray, etc.), ambient temperature and grouping.

- Apply correction factors for elevated ambient temperature, multiple loaded cables in a raceway or tray, or other derating conditions. Some implementations of the calculator may expose separate fields for these factors.

- Confirm short-circuit withstand and protective device coordination using equipment data.

If the Cable Sizing Calculator suggests a noticeably smaller cable than your ampacity or short-circuit checks allow, you should favor the larger size. Voltage drop and ampacity are not competing requirements so much as two sides of the same safety-and-performance coin.

A good workflow is:

- Use the calculator to estimate a voltage-drop-compliant cable area.

- Round up to the next standard conductor size from a table.

- Verify that this standard size meets ampacity and short-circuit requirements.

- Re-check voltage drop for the final chosen size (using the check mode).

This loop gives you confidence that the number on the screen corresponds to a real, catalogued cable that satisfies all major design checks, not just the mathematics of voltage drop.

Single-phase vs three-phase cable sizing

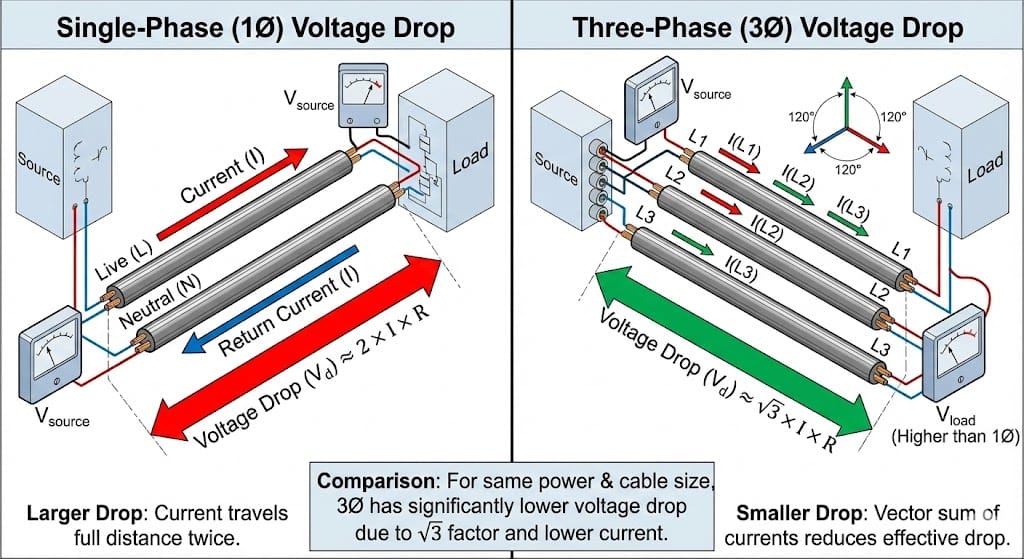

The Cable Sizing Calculator lets you specify system type as single-phase or three-phase. This choice affects the geometry factor \(k_{\phi}\) and therefore the computed voltage drop for the same current, length and cable size.

For a single-phase, two-wire circuit, current must travel out and back through separate conductors. The effective path length is therefore doubled, which is represented by a factor of 2 in the voltage drop equation:

For a balanced three-phase system, the line-to-line voltage drop magnitude is proportional to \(\sqrt{3}\, I R\), which is slightly less than the single-phase case with the same per-conductor resistance.

The calculator incorporates this difference automatically when you change the System Type selector. That means:

- For the same cable size, current and one-way length, a three-phase circuit will usually have a slightly lower voltage drop than a comparable single-phase one.

- If you convert a load from single-phase to three-phase, the same cable may deliver acceptable voltage drop at a higher kW rating, depending on how current and voltage are adjusted.

Always match the system type in the calculator to the actual circuit topology in your design (e.g., single-phase feeder, three-phase motor circuit, three-phase panel feeder, etc.). Mixing them will give misleadingly optimistic or pessimistic results.

How material, length and load shape your cable size

Once you understand the formulas, it becomes clear which parameters matter most when using the Cable Sizing Calculator. Three of them dominate the result: conductor material, cable length and load current.

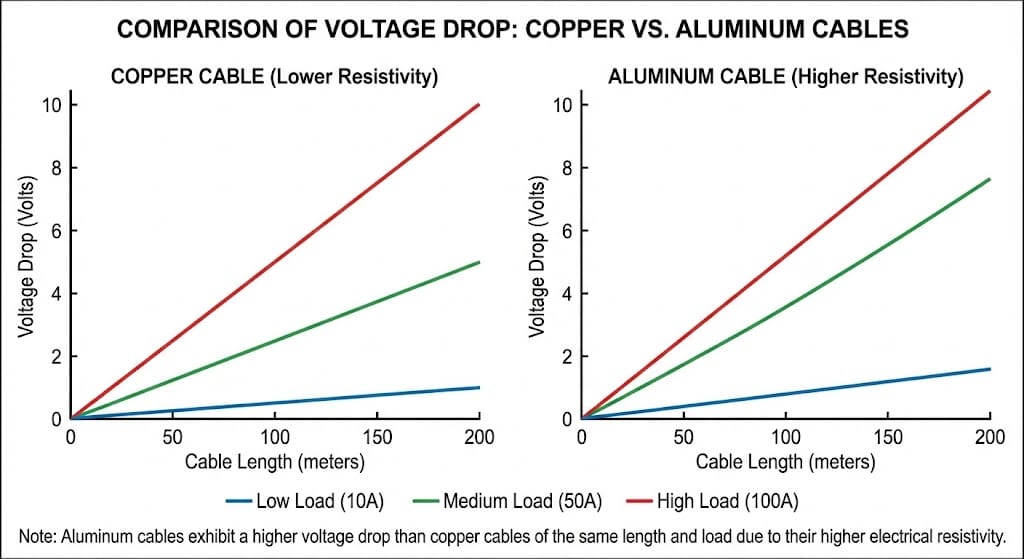

Conductor material. Copper and aluminum have different electrical resistivities, so for a given area and length, aluminum exhibits higher resistance and therefore higher voltage drop. To maintain the same drop limit, an aluminum cable needs a larger cross-section than a copper one. This is why switching material in the calculator can change the recommended area even if all other inputs stay identical.

Cable length. Voltage drop is directly proportional to length \(L\). Doubling the one-way length doubles the voltage drop for the same current and cable size. For long rural feeders, parking lot lighting, or remote equipment, this often forces a designer to go up several cable sizes just to keep the drop under control. For short runs in a compact panelboard room, voltage drop may be negligible compared to ampacity constraints.

Load current. Heavier loads draw more current, which also raises voltage drop linearly. When equipment is upgraded, it is common to re-evaluate both ampacity and voltage drop. Plugging the new load current into the calculator quickly reveals whether the existing cable is still acceptable.

Other factors that influence effective resistance include conductor operating temperature, strand shape, and proximity effects, but these are typically wrapped into the resistance values published by manufacturers or implied in standard tables. The calculator uses representative resistivity values for copper and aluminum at ordinary operating temperatures to give a good engineering estimate.

As a rule of thumb:

- Longer runs, higher currents, lower allowable voltage drop, or aluminum conductors all push cable size upward.

- Shorter runs, lighter loads, higher supply voltage, and slightly relaxed drop limits can permit smaller cables, within code and ampacity bounds.

When you experiment with the calculator, try changing one parameter at a time to see its effect. This builds intuition you can carry into future designs, even when you are working from printed tables or manufacturer software.

Cable sizing calculator worked examples

The best way to see how the Cable Sizing Calculator behaves is to walk through a couple of realistic scenarios. The examples below use typical distribution voltages and loads, but you can adapt the same logic to your own numbers. To reproduce the calculations, simply enter the same values into the calculator above and compare the results.

Example 1 – Sizing a copper cable for a small three-phase motor

Suppose you are feeding a 15 kW three-phase motor from a 400 V supply. The design load current, including a reasonable margin, is approximately 30 A. The motor control center is 45 m away from the motor (one-way). You want to limit voltage drop on this feeder to about 3 %.

To size the cable by voltage drop, you would:

- Select Size cable by voltage drop as the calculation mode.

- Set System Type to Three-phase and Material to Copper.

- Enter 400 V supply, 30 A load current and 45 m cable length.

- Set allowable voltage drop to 3 % and run the calculation.

The calculator follows the same voltage-drop formula introduced earlier. A simplified three-phase estimate looks like:

where \(\rho_{\text{Cu}}\) is the resistivity of copper expressed in compatible units (for example \(\Omega\cdot\text{mm}^2/\text{m}\)). The calculator performs the unit juggling and reports a minimum area in mm². You would then round up to the next standard size from your preferred cable table.

Result (conceptually): for this combination of current, length, material and drop limit, a mid-sized copper conductor is typically sufficient. If you shorten the run or relax the drop limit slightly, the required area will fall; if you double the length, it will rise.

Example 2 – Checking voltage drop on an existing aluminum feeder

In this case, imagine you already have a buried aluminum feeder in place feeding a small panel at the far end of a property. The circuit is single-phase 230 V, with a design load of 40 A. The one-way length is 60 m, and the installed cable size is 35 mm² aluminum. You want to confirm that the voltage drop stays within a sensible limit.

To use the calculator in check mode:

- Choose Check voltage drop for an existing cable as the calculation mode.

- Select Single-phase and Aluminum as system type and material.

- Enter 230 V supply, 40 A load current and 60 m length.

- Enter 35 mm² as the existing conductor area and run the calculation.

The calculator computes the resistance of the 35 mm² aluminum conductor for the specified length, applies the single-phase geometry factor, and reports both the absolute voltage drop and the percentage of supply voltage:

Result (conceptually): if the calculated percentage is comfortably below your design limit, the existing cable is acceptable from a voltage-drop standpoint. If not, you may need to limit the load, reduce the length, or replace the cable with a larger cross-section.

Cable sizing & Cable Sizing Calculator – frequently asked questions

How do I choose between copper and aluminum in cable sizing?

Copper and aluminum can both be good choices when sized correctly. Copper has lower resistivity, so you get less voltage drop and more ampacity for the same cross-section, but it tends to be heavier and more expensive. Aluminum is lighter and often cheaper per ampere-meter but needs a larger cross-section for the same performance. In the Cable Sizing Calculator, switching from copper to aluminum while holding current, length and voltage drop limit constant will usually increase the required area. Always combine the calculator’s recommendation with code-based ampacity checks and manufacturer guidance for terminations and lugs.

What is a typical allowable voltage drop for power cables?

There is no single universal limit, but many design practices keep feeder voltage drop within a few percent of supply and ensure that the total feeder plus branch circuit drop remains only slightly higher. Sensitive electronic equipment, long lighting runs, and motor circuits may justify tighter limits, while very short runs might tolerate slightly more. The Cable Sizing Calculator lets you choose the percentage that matches your project philosophy and local standards. If you are unsure, start with a conservative value and then verify that loads still receive adequate voltage under worst-case conditions.

Does cable length really matter, or is ampacity the main concern?

Ampacity is absolutely essential for safety, but cable length is a major driver of voltage drop. For a given current and cable size, voltage drop is directly proportional to one-way length, so long rural runs and large parking lot feeders are much more likely to have voltage-drop issues than short panel feeders. The Cable Sizing Calculator helps you quantify this effect. For very short runs, ampacity may dominate the design; for long runs, voltage drop often forces you to choose a larger cable than the minimum required solely by ampacity tables.

Can the Cable Sizing Calculator replace code tables and manufacturer data?

No. The Cable Sizing Calculator is an engineering aid, not a substitute for applicable electrical codes, standards, or detailed manufacturer literature. It is excellent for exploring “what-if” scenarios, estimating a sensible starting cable size, and checking voltage drop on existing runs. However, final designs should always reference official ampacity tables, installation correction factors, short-circuit ratings, mechanical constraints and any project-specific requirements. Think of the calculator as a fast, transparent way to handle the voltage-drop math that complements—not replaces—formal design steps.

How accurate are cable sizing results compared to specialized software?

For straightforward feeders and branch circuits, the Cable Sizing Calculator typically provides good engineering-level estimates that agree closely with detailed hand calculations and simplified software tools. Specialized commercial packages may include additional refinements such as more granular resistance data, harmonic loss models, temperature-dependent properties, and automatic lookup of exact catalog part numbers. The calculator is designed to be transparent and easy to understand, so you can see how changes in voltage, current, length, material and drop limit affect the result without getting lost in configuration menus.

What should I do if the calculator suggests a non-standard cable size?

The calculator operates in continuous units like mm², so it may output an area that falls between standard commercial sizes. The usual next step is to round up to the next standard size in your preferred cable range, then use the check mode to recompute voltage drop for that actual size. If the new voltage drop is acceptable and the cable meets ampacity and installation requirements, you have a practical design. If not, repeat with the next larger standard size or revisit assumptions such as allowable drop, routing, or load magnitude.